Poggio Mario S.r.l.

QUATTRO M

Rinsers - Sterilizers - Blowing machines (Air-rinsers)

Besides glass and PET bottles, they can process also cans and jars as well as canisters and bins with special shapes.

They are manufactured with high quality materials such as AISI 304 and/or AISI 316 stainless steel, and materials for food contact. The chassis is completely made of stainless steel with transparent panels of high resistance polycarbonate for a good vision during the operation.

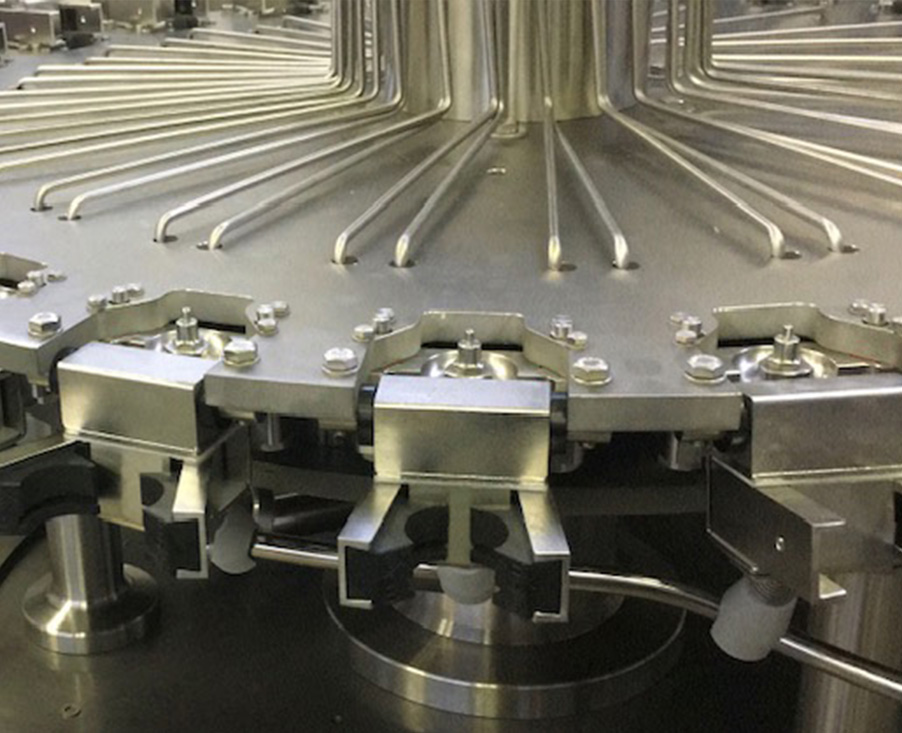

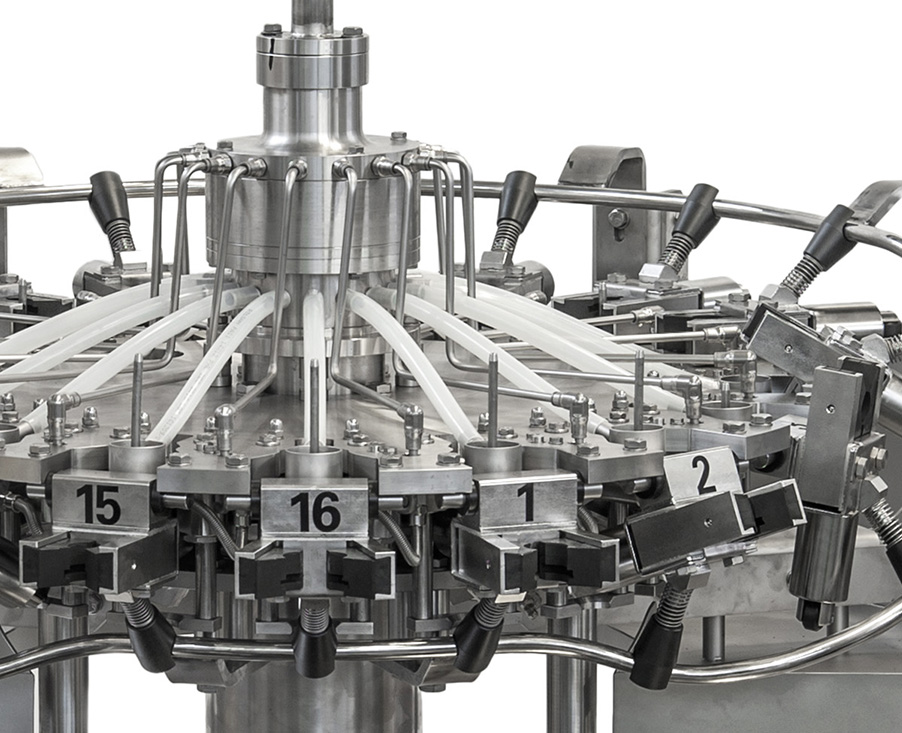

The machines of the "QUATTRO M" series work with rotary system. For perfect

centring, the gripper with symmetric opening takes the bottles when they are

still guided by the inlet star-wheel.

The grippers seize the containers by the neck, overturn them by means of a

shaped twist-cam, and guide them with the mouth in correspondence to the

spraying nozzle activated only at the presence of the bottle (no-bottle no-spray).

The rinsing liquid is distributed through a valve system or through a timed

rotating joint, depending on the needs.

The distribution through valves reduces the number of sets for format change of the neck of the bottle and the wear of the grippers dramatically.

The standard equipment of the machines includes:

- No-bottle no-spray function

- Inclined collection tank for complete discharge

- Photocells at the machine inlet and outlet for the automatic operation of the line

- Inverter for the electronic regulation of the production speed

- Electrical regulation of the height of the carrousel to allow processing bottles and containers of different heights

- Fluid interception valves for spraying block when the machine is at standstill

- Tool-free format change

- Safety sensors on the mechanical parts for protection in case of exceeding mechanical efforts

All machines of the "QUATTRO M" series are available in stand-alone version or as turrets to be mounted on monoblocks/triblocks.

For the product that do not allow wetting the container, the "QUATTRO M" machines can work as blowing machines (air rinsers) with filtered and/or ionized air and, if requested, they can be equipped with an under-the-neck aspiration system.

Optional

TWO-TREATMENT RINSING

The circuits distributing the fluids of the machines with two or more treatments are COMPLETELY separated to prevent the fluids from mixing dangerously with the consequent contamination of the containers and of the bottled products.

MOBILE NOZZLE

The injector can enter the bottle with a stroke of around 110mm, operated through a cam with controlled return, without any movement springs.

RECYCLING

Rinsing liquid recycling, filtering, and re-using system.

EXTERNAL WASHING

Tunnel for the rinsing of the external surface of the containers

LAST DROP BLOWING-OFF

ASPIRATION OF THE LAST DROP WITH RECYCLING OF THE PRODUCT

VAPOUR ASPIRATION HOOD

RINSING MONOBLOCKS for more complex rinsing and sterilization cycles by combining more rinsing turrets on the same machine

ELECTRONICALLY OPERATED MACHINES WITH ELECTROPNEUMATIC DISTRIBUTION WITH TWO TREATMENTS OR MORE